Brand Name: OMS

Model Number: --

Place of Origin: Guangdong, China (Mainland)

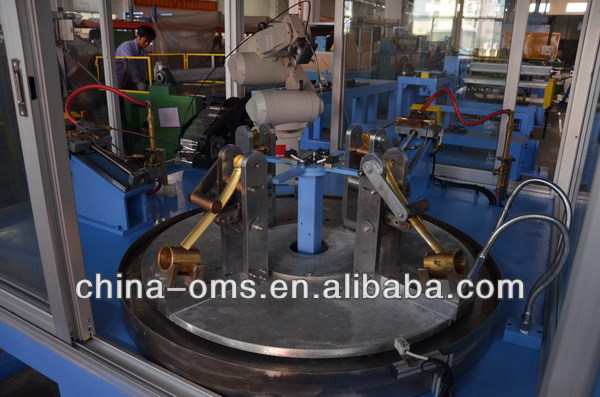

Automatic welding mchine

This automatic welding machine is equipped with a robot. It realizes accurate control of heating time, welding filler feeding amount and time, and effective control of air flow. This leads to good control of welding temperature, and the formation of filler molten pool. The welding products are of good quality and stability.

The robot enables welding from any angle. It can be utilized in welding, soldering, or brazing various kinds of products. We can customize the machine to meet your specific requirements.

Welding product: even filler flow, well filled molten pool, no dry joint.

Machine features:

1. Mechanical section

Fully automatic robot can perform welding from any angle.

Quick loading and unloading of the workpiece.

Automatic welding wire feeding device, which can accurately control the filler amount and feeding time.

Pneumatic welding gun, which reaches to the welding point quickly.

2. Combustion system

Fully automatic control of gas flow amount, which controls the flame.

Strong flame and weak flame can be switched automatically. When the welding gun is waiting for the next work piece, the weak flame mode will be turned on automatically.

Nitrogen is used to extinguish the flame (to avoid backfire).

Air pressure alarm.

Automatic device for feeding welding paste, which enhances the welding results.

3 Control system

HMI touch screen , easy for operation

PLC control

The technical parameters can be adjusted. For example, the movement cycle time and speed of the fixture, the distance between the nozzle and workpiece, the feeding speed, timing, and height of welding filler, the distance between the welding filler and workpiece, the flow of fuel gas and nitrogen, etc.

The technical parameters can be stored and accessed.

Fault alarm system .

4. Safety guarantee measures

Gas circuit.

Strick leak detection is carried out before delivery. The fuel gas channel and oxygen channel are installed with anti-backfire valves.

Pressure alarm.

The pressure of the air circuit system is supervised. The alarm will ring when certain pressure is out of the set range.

Switch between strong flame and weak flame

When the welding gun is working, it turns to strong flame mode; when the gun is moving or waiting, it turns to weak flame. This function saves gas and prevents danger in the case of wrong operation by workers.

Nitrogen extinguisher

The use of nitrogen to extinguish the gas prevents backfire.

Power-off protection

When power failure happens, the machine will automatically fill the air circuit system with nitrogen to extinguish the flame immediately, so as to avoid backfire.

Emergency stop

Emergency stop switch is installed in two obvious places. Under emergency, the electricity and air system can be shut down instantly.

5. The use of high standard components make the machine highly reliable.

PLC and HMI: OMRON, Mitsubishi

Solenoid Valve: . SMC, ASCO ,etc

Electric components: Schneider, Mitsubishi, etc,

Pneumatic parts: FESTO, SMC

Robot: Mitsubishi

Cusomer case: Brass faucet